Laser Marking Medical Devices, Medical Instruments and Medical Components

The use of laser marking has become a crucial of the medical industry. Laser marking offers accuracy, permanency and repeat-ability making them essential when medical tools and devices need to be laser marked with serial numbers or bar codes, or company logo for trace-ability. Laser marking medical device procedures are critical to the medical industry because they make it possible to provide a contrasting surface annealed laser mark on stainless steel and titanium. Using lasers consistent with the approved guidelines, manufactures can be confident that the final product will be FDA compliant.

Manufacturers must utilize medical device marking that can withstand the rigors of repeated sterilization while adhering to a medical engraving process that is FDA approved. Laser marking medical device protocols are governed by strict requirements. Stainless steel and titanium medical devices can be marked with non-contaminating surface annealed dark marking that can still provide adequate contrast for legibility without disrupting or adding material to the surface of the medical device.

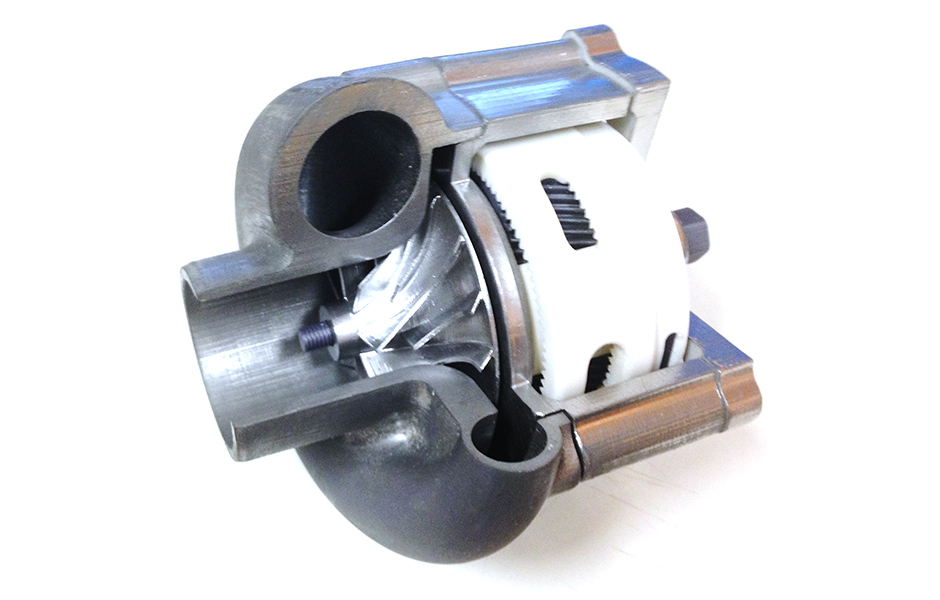

With more than 35 years of experience Laser Impressions has defined the best laser processing variables to achieve optimal results in medical device marking. Medical components, surgical instruments, bone screws, or even implants that are made from titanium, stainless steel, or engineered plastics can be engraved using laser technologies that are capable of producing superior legibility and contrast on either flat or curved surfaces. Bar codes, serialization, logos, and any other marking you can imagine can be etched into the surface of metal or plastic medical devices.

Dark surface annealed laser marking can be used to create a smooth “stain” with excellent contrast on stainless steel and titanium. This can be useful if there is a concern about an etched surface collecting organic materials such as blood or tissue. Messages can also be etched at .005 inches or deeper if durability is an issue. Whether it is putting a logo on a surgical instrument or a part number on a tool handle, smooth or flat, metal or plastic, Laser Impressions can create a lasting image on your medical devices.

Trazza Design provides laser engraving and marking for medical devices, medical instruments and medical components.

Leave A Comment